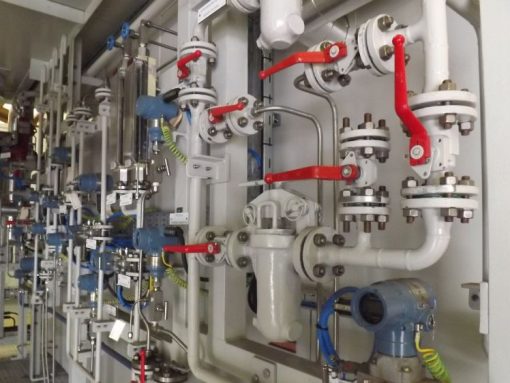

Our Duragas machines can be fitted with a combination of the following seals. Seals can generally be either single or dual. Two independent sealing systems can be deployed for dangerous gases.

We can offer a pressurised liquid barrier system in accordance with API 682 seal plan 53B (self-circulating), or plan 54 (pumped) if required.

For double dry mechanical seals we can offer a pressurised gas barrier system in accordance with API 682 seal plan 74

A hermetic seal is formed by the containment shell (can / membrane / shroud) of the mag’ drive. The compressor is said to be ‘sealless’ at the drive shaft. Compliance with API Standard 685 is available. We also offer a leakage-detection system for high-pressure applications.

Double Mechanical Seal

Magnetic Drive Coupling

Purged Inner Seals

Pressurised gas barrier system in accordance with API Std 682 piping plan 74

Pressurised seal oil barrier system (self-circulating), in accordance with API Std 682 piping plan 53B

Pressurised demineralised water barrier system with circulating pump, in accordance with API Std 682 piping plan 54